Reliable Surge Protection for Industrial and Power Applications #

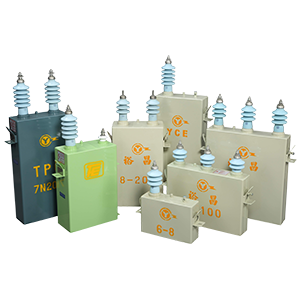

Yuhchang surge absorbing capacitors, also known as surge protection capacitors, are engineered to deliver robust protection for high-voltage motors, transformers, and generators. These capacitors are specifically designed to absorb and mitigate voltage surges that may arise during breaker operations or as a result of lightning strikes. By connecting between the line and ground, they help shield critical equipment from potentially damaging voltage spikes, thereby enhancing operational reliability and extending equipment lifespan.

Key Advantages of Yuhchang Surge Protection Capacitors #

- Global Standards Compliance: Manufactured in accordance with JEM 1362 and IEC 60871 standards, ensuring compatibility and reliable performance worldwide.

- Quality Assurance: Certified under ISO 9001:2015, reflecting a strong commitment to quality management.

- Versatile Installation: Suitable for both indoor and outdoor environments, up to 1000 meters above sea level.

- Wide Operating Range: Efficient operation at 50/60Hz frequencies and ambient temperatures from -20℃ to +50℃.

- Durable Construction: Utilizes high-grade polypropylene film as the dielectric and is filled with non-PCB insulation fluid for environmental safety and longevity.

- Corrosion Resistance: Housed in stainless steel cases with epoxy and urethane paint systems, offering resistance to corrosion, acids, alkalis, and harsh weather conditions.

- Maintenance-Free: Sealed design prevents oil leakage even at elevated temperatures, ensuring long-term, maintenance-free operation.

- Enhanced Safety: Features a wet process porcelain bushing in Munsell 5B 8/4 (baby blue) for both functional and aesthetic value.

Applications #

Yuhchang surge absorbing capacitors are ideal for a range of industrial applications where voltage surge protection is essential. They are widely used to safeguard transformers, high-voltage motors, and generators in sectors such as energy, manufacturing, and any field that relies on complex electrical machinery requiring stable voltage regulation. By integrating these capacitors, businesses can protect valuable assets, reduce downtime, and maintain high productivity levels.

For more information or to discuss your specific requirements, contact us.

Specification and Performance Standards #

| Parameter | Specification |

|---|---|

| Standards | JEM 1362, IEC 60871 |

| Factory Approval | ISO 9001:2015 certified |

| Usable Altitude & Place | Up to 1000m above sea level; suitable for indoor/outdoor use |

| Frequency | 50/60Hz |

| Capacitance Tolerance | -5% to +10% (In three-phase units, the ratio of maximum to minimum capacitance between any two terminals <1.08) |

| Ambient Temperature | -20℃ to +50℃ (24-hour average below 45℃; other categories available on request) |

| Maximum Permissible Voltage | 110% of rated voltage (average over 24 hrs); 115% (30 min/24 hrs); 120% (within 5 min); 130% (within 1 min); 182% (within 2 sec). Values above 115% should not occur more than 200 times during the capacitor’s life. |

| Maximum Permissible Current | 135% of rated current |

| Dissipation Factor | Less than 0.5% |

| Temperature Rise | Below 25℃ at ambient temperature 35℃ |

| Sealing | No oil leakage after heating at 80℃ for 4 hours |

| Insulation Resistance | Above 1000 MΩ |

| Residual Inductance (T-C) | Less than 2 μH |

| Series Resistor | Internal or external, as specified by manufacturer |

| Test Voltage (Between Terminals and Case) | AC voltage test for 1 minute |

Test Voltage Table #

| Line Voltage (kVac) | Test Voltage (kVac) |

|---|---|

| 3.3, 3.45 | 16 |

| 4.16 | 18 |

| 6.0, 6.6, 6.9 | 22 |

| 11, 11.95 | 28 |

| 13.8 | 33.5 |

| 15 | 35 |

| 22 | 50 |

| 24 | 54 |

Construction Details #

| Component | Description |

|---|---|

| Dielectric | Polypropylene film |

| Insulation Fluid | Non-PCB fluid |

| Bushing & Color | Wet process porcelain, Baby blue (Munsell 5B 8/4) |

| Case Material | Stainless steel |

| Paint / Color | Epoxy/urethane system, sand color (Munsell 7.5Y 7/2), resistant to corrosion, acids, alkalis, and weather |

| Earth Connection | One side bracket with ground terminal (option for unpainted area under brackets for earthing) |

For a comprehensive overview, download the catalog or contact us for further assistance.